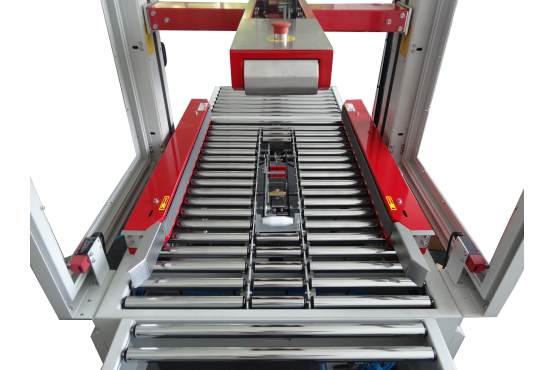

KPM-105SDR (All-Automatic Machine)

Case Sealing - easy and time-saving

Our semi-automatic case sealers are the ideal solution for professional case sealing. Depending on the machine type, the case sealer is driven laterally or from above and below. The case sealers can be adjusted individually to the respective case sizes. The shipping cases are closed by a machine adhesive tape which quickly and securely bonds the lower and upper flaps. The machine line guarantees ergonomic work (no constant lifting of heavy cases), clean and straight adhesive seams and a low-noise unwinding of the adhesive tape.

Technical Details

- maintenance-friendly, low spares costs

- adjustable tape tension

- 2 tape dispenser (above / below)

- quick format changes via handwheel or photoelectric technology

- including product infeed and outfeed conveyor belt

- adhesive tapes (50 mm width / optional 75mm)

- conveyor belt direction (right / left)

- height-adjustable wheeled supporting feet

- case erector (KPM-116) available on demand

KPM-105SDR: Technical Data

| Model: | KPM-105SDR |

|---|---|

| Usable tape: | PP / PVC / Hotmelt |

| Inner tape reel diameter: | 76 mm |

| Minimum case dimensions (Wx H): | 110 x 120 mm* |

| Maximum case dimensions (W x H): | 600 x 600 mm* |

| Machine size (L x W x H): | 1860 x 1030 x 1550 mm |

| Maximum case weight (approx.): | 40 kg |

| Arrangement of drive belts: | lateral |

| Case format adaption: | automatic |

| Transport speed: | 23 m / minute |

| Maximum reel height: | 880 mm |

| Supply voltage: | 230 V |

| Air pressure (dry air): | 6,0 bar |

| Connected load (maximum): | 0,40 kW |

| Machine weight (approx.): | 195 kg |

| Packing capacity: | up to 20 pieces / minute** |

* It is not possible to combine all maximum dimensions

** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling