Machines for the production of FFP2 face masks

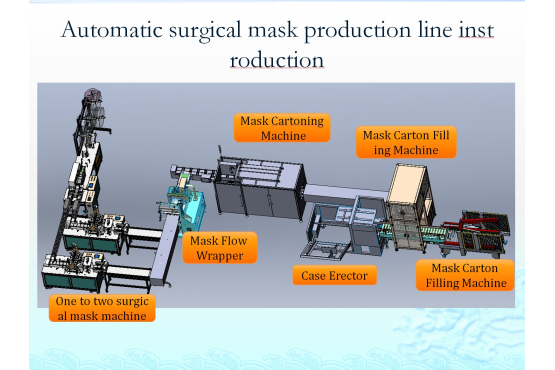

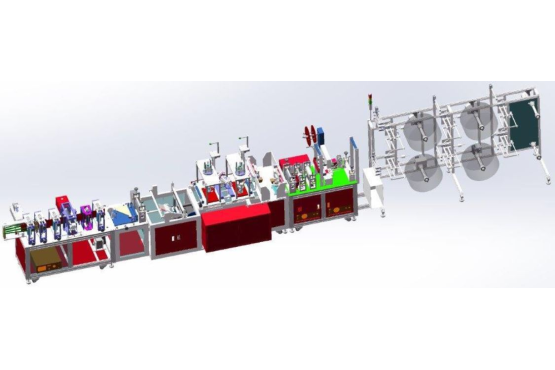

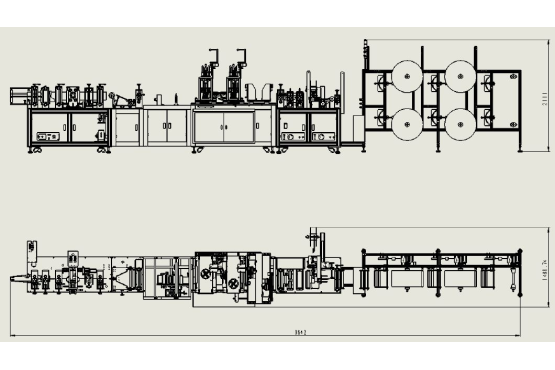

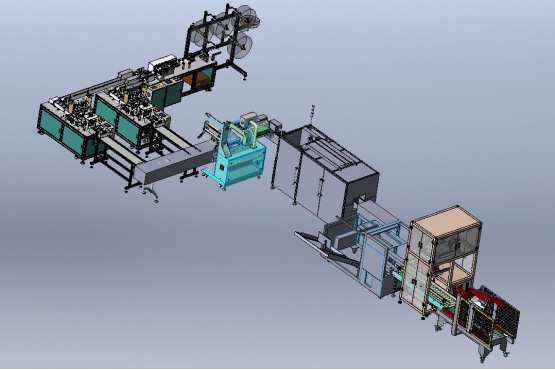

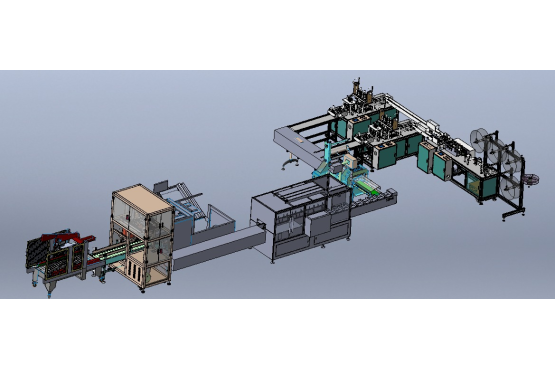

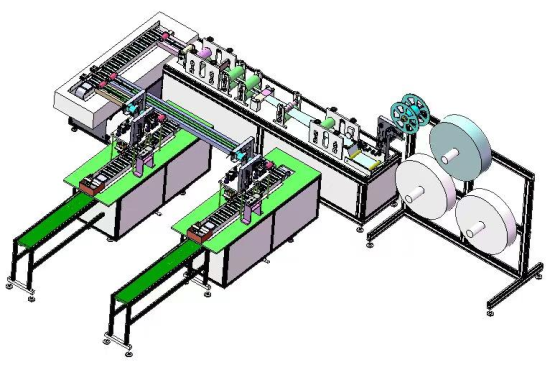

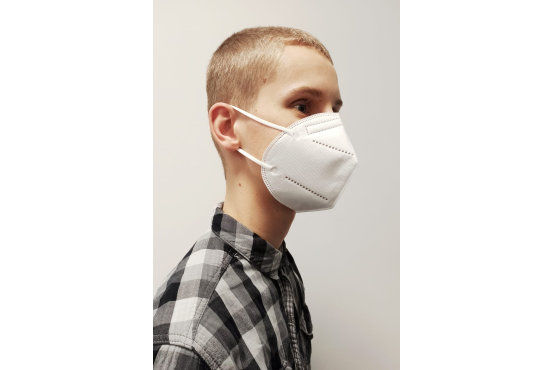

Our group of companies has rapidly developed a new production line for the manufacture of face masks. The surface, filter and inner layers of the masks are automatically aligned and fed with 4 rolls of fabric. Our machines guarantee a mask production with even pressure and symmetrical contours. The masks are first cut from continuous rolls and then sent to the next step where the air bands are welded together. Then the ear band is automatically welded to the face mask and cut by ultrasonic. This process contributes to a high production efficiency so that our machines can produce high volumes in short time intervals. Our masks can be worn without any concerns as they are manufactured using the latest melt blown technology according to FFP2 standards.

Specifications:

You do not have sufficient space for an in-house mask making machine but need a large number of face masks at short notice? As a manufacturer we have the possibility to supply large capacities of masks.